STT Series Flooded (OPzS Battery)

The combination of the tubular positive plates and the lead selenium/ low antimony alloy provides the best possible combination in lead acid plate technology. The battery world favors tubular positive plates for flooded, gel and AGM applications. STT batteries are manufactured in accordance with OPzS DIN 40736 standards.

- 20 year design life @ 77° F

- Watering intervals: 1–3 years

- Leak-proof post seal

- 1200+ cycles @ 80% DOD

- 2000+ cycles @ 60% DOD

- 100%+ capacity upon delivery

- No positive plate growth damage

- Tank formed plates

- Safe: zero voltage exposed to personnel

- Stationary Battery Analyzer

- Flip-top, easy-fill, flame arrestor vent caps

- Withstands high temperature applications better than lead-calcium batteries

- Typically in stock and ready to ship!

- Switchgear / Substations

- Power Generation

- Microwave Relay Sites

- Telecommunications

- Solar / Photovoltaic

- Oil and Gas

| Part No. | 8 Hr Ah Rate | V | Battery DimensionsL x W x H (in.) | Weight w/Electrolyte (lb.) | Electrolyte Weight (lb.) | Electrolyte(Gallons) |

| STT12V50 | 55 | 12 | 10.7 x 8.08 x 15.1 | 86.0 | 23.8 | 2.3 |

| STT12V100 | 110 | 12 | 10.7 x 8.08 x 15.1 | 107 | 22.5 | 2.2 |

| STT12V150 | 165 | 12 | 15.0 x 8.08 x 15.1 | 149 | 31.7 | 3.1 |

| STT6V200 | 220 | 6 | 10.7 x 8.08 x 15.1 | 101 | 24.2 | 2.3 |

| STT6V250 | 275 | 6 | 15.0 x 8.08 x 15.1 | 130 | 31.9 | 3.1 |

| STT6V300 | 330 | 6 | 15.0 x 8.08 x 15.1 | 144 | 30.4 | 2.9 |

| STT2V100 | 110 | 2 | 4.06 x 8.11 x 16.1 | 28.8 | 12.3 | 1.2 |

| STT2V150 | 165 | 2 | 4.06 x 8.11 x 16.1 | 34.2 | 11.1 | 1.1 |

| STT2V200 | 220 | 2 | 4.06 x 8.11 x 16.1 | 39.6 | 9.90 | 1.0 |

| SST2V250 | 275 | 2 | 4.89 x 8.11 x 16.1 | 46.2 | 11.0 | 1.1 |

| STT2V300 | 330 | 2 | 5.71 x 8.11 x 16.1 | 55.0 | 13.2 | 1.3 |

| STT2V350 | 395 | 2 | 4.89 x 8.11 x 20.7 | 61.6 | 14.3 | 1.4 |

| STT2V420 | 475 | 2 | 5.71 x 8.11 x 20.7 | 73.7 | 17.6 | 1.7 |

| STT2V490 | 550 | 2 | 6.54 x 8.11 x 20.7 | 85.8 | 22.0 | 2.1 |

| STT2V500 | 550 | 2 | 5.71 x 8.11 x 27.6 | 92.6 | 28.7 | 2.9 |

| STT2V600 | 660 | 2 | 5.71 x 8.11 x 27.6 | 102 | 26.4 | 2.6 |

| STT2V700 | 755 | 2 | 8.27 x 7.52 x 27.6 | 132 | 37.5 | 3.8 |

| STT2V800 | 865 | 2 | 8.27 x 7.52 x 27.6 | 141 | 35.2 | 3.4 |

| STT2V900 | 975 | 2 | 8.27 x 9.18 x 27.6 | 161 | 44.1 | 4.5 |

| STT2V1000 | 1090 | 2 | 8.27 x 9.18 x 27.6 | 170 | 44.0 | 4.3 |

| STT2V1200 | 1310 | 2 | 8.27 x 10.9 x 27.6 | 203 | 52.8 | 5.1 |

| STT2V1375 | 1605 | 2 | 8.27 x 10.9 x 33.5 | 244 | 77.1 | 7.8 |

| STT2V1500 | 1755 | 2 | 8.27 x 10.9 x 33.5 | 247 | 66.0 | 6.4 |

| STT2V1750 | 2047 | 2 | 8.35 x 15.7 x 32.6 | 296 | 78.0 | 7.5 |

| STT2V1875 | 2200 | 2 | 8.35 x 15.7 x 32.6 | 328 | 101.4 | 10.2 |

| STT2V2000 | 2340 | 2 | 8.35 x 15.7 x 32.6 | 330 | 88.0 | 8.5 |

| STT2V2250 | 2630 | 2 | 8.35 x 19.2 x 32.6 | 405 | 130.0 | 13.1 |

| STT2V2500 | 2920 | 2 | 8.35 x 19.2 x 32.6 | 418 | 110 | 10.6 |

| STT2V3000 | 3585 | 2 | 8.35 x 22.7 x 32.6 | 495 | 136 | 13.2 |

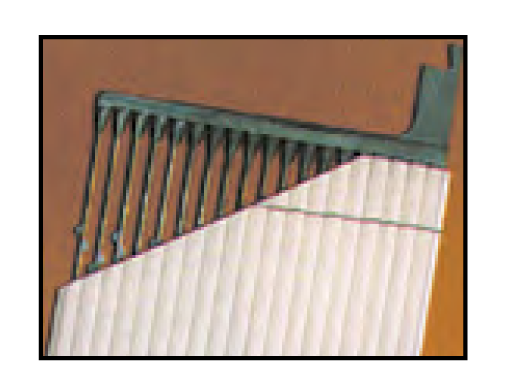

| Positive Plate | Tubular plate with selenium/low antimony alloy (0.34" thick) |

| Negative Plate | Pasted flat radial structure |

| Separation | Microporous combined with corrugated separator |

| Case Material | Styrene-acrylonitrile (SAN), impact resistant |

| Cover Material | Styrene-acrylonitrile (SAN) |

| Specific Gravity | 1.240 S.G. @ 77°F |

| Post Design | Leak-proof with brass insert |

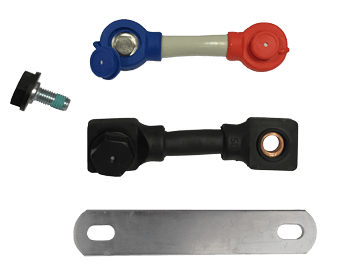

| Intercells | Fully insulated flexible copper cables (uninsulated bars optional) |

| Vent Caps | Flip-top flame arrestor with dust cap |

| Temp. Range | −4° to 131° F (68° to 77° F recommended) |

| Float Voltage | 2.23 V/cell |

| Equalize Voltage | 2.33–2.40 V/cell |

| Part No. | Description |

| Z1G | Hydrometer with glass float (1.100–1.320 scale) |

| HY-HOLDER | Hydrometer holder with drip cup |

| 1353 | Thermometer w/SG correction factor table (-20° to 130° F) |

| STRAP-6FT | 6 ft. lifting strap (for P/Ns STT2V100 through STT2V490) |

| STRAP-8FT | 8 ft. lifting strap (for P/N STT2V600 and larger) |