Battery Spill Containment

The Uniform Fire Code (UFC) Article 64, Section 104.d and 104.e requires lead-acid battery installations with more than 100 gallons of electrolyte be equipped with a “liquid-tight” spill-control barrier system. It also requires an approved method, capable of neutralizing a spill from the largest lead-acid battery.

In response to these new requirements, Exponential Power offers a spill containment system solution. Exponential Power’s system is quick and easy to install with new battery racks.

How Our System Works

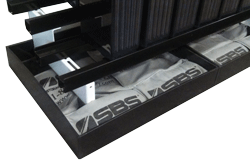

Exponential Power stocks different size spill pans that can be placed together in multiple combinations to form different spill containment system lengths and widths.

We provide pillows and connectors that hold the pans together.

Your rack will fit inside our spill containment system. If you are mounting the racks to the floor, you drill through the pans where needed and silicone the bolt and hole to provide a 100% leakproof system.

Battery Spill Containment System

Example System Includes:

A: 42″ x 28″ x 4″ pan (Qty. 1)

B: 25″ x 28″ x 4″ pan (Qty. 1)

C: 27″ connector (Qty. 1)

D: 12″ x 12″ pillows (Qty. 10)

Spill Containment Inside Battery Cabinet

- Welded 5/16″ thick HDPE pans in multiple sizes

- 12″ x 12″ Flame retardant acid absorbing/neutralizing pillows (10″ x 10″ Ni-Cd pillows available as an option)

- Complies with EPA, OSHA, and Uniform Fire Code 64

- Acid tight, 4″ tall barrier protects from corrosion

- Quick and easy installation

- Cost effective solution to electrolyte spills

- Custom sizes available

Resources

OPzS Flooded Batteries in a Stationary Battery Rack with spill containment inside a Battery Enclosure.